In the era of Industry 4.0, barcodes have become an indispensable tool for businesses to manage goods, control inventory, and optimize operational processes. Along with that, barcode scanning technologies continue to evolve and improve.

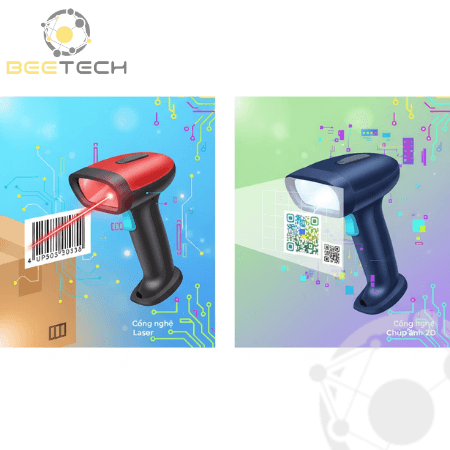

The two most common types of scanners today are laser barcode scanners and 2D image scanners. Each offers unique advantages suited to different operational needs. This article will help you understand the differences between these two technologies and choose the most suitable barcode scanning solution for your business.

Overview of the two barcode scanner types

Laser barcode scanners operate based on the principle of light reflection. When a laser beam hits the barcode surface, the alternating light and dark areas reflect the beam differently. The optical sensor inside the scanner captures these variations and converts them into digital data. Laser technology is known for its high speed and accuracy when reading 1D barcodes, the traditional type consisting of parallel lines.

In contrast, 2D image scanners use image sensors (similar to a camera) to capture the entire barcode surface and then decode it using image-processing software. This technology can read both 1D and 2D codes (such as QR Codes, Data Matrix, or PDF417) and works effectively on various surfaces and materials.

Reading capability and scanning speed

If your business mainly uses 1D barcodes and requires fast, continuous, and accurate scanning for example, in production lines or retail checkouts laser scanners are the ideal choice. With focused light beams, these scanners can read hundreds of barcodes per second, saving time and boosting productivity.

However, if you need to read barcodes from multiple angles or scan different types of codes, 2D image scanners are superior. These devices don’t require barcode alignment; simply place the code within the scanning area, and the device will automatically capture and decode it even if the code is rotated, printed in reverse, or displayed on a smartphone screen.

Barcode condition and surface quality

In warehouses, logistics, or manufacturing environments, barcodes often get scratched, smudged, or printed on curved or reflective surfaces. This is a weakness of laser scanners since light reflection requires clean, high-contrast barcodes. When codes are damaged, the laser beam struggles to read them accurately, leading to data errors or missed scans.

Conversely, 2D image scanners excel at “error correction.” By capturing the full image and applying intelligent algorithms, they can decode blurry, faded, or misaligned barcodes even those printed on curved surfaces or displayed on LED, LCD, or mobile device screens something laser scanners cannot achieve.

Scanning distance and lighting conditions

One major advantage of laser scanners is their long scanning range, which can extend from a few centimeters to over 10 meters, depending on the model and beam power. This makes them ideal for scanning pallets in high racks, reading barcodes from a distance on packaging lines, or identifying container tags in transportation.

Meanwhile, 2D scanners generally have a shorter range (around 5–80 cm). However, they perform well under varying lighting conditions, working reliably in low-light or overly bright environments. This makes them particularly useful in retail stores, hospitals, or laboratories where lighting is inconsistent.

Durability and investment cost

Laser scanners contain moving mechanical components such as spinning mirrors, which are subject to wear and tear over time, especially in environments with vibration or dust. On the other hand, 2D image scanners use static CMOS sensors with no moving parts, resulting in higher durability and lower maintenance requirements.

In terms of cost, laser scanners are generally more affordable, making them suitable for retail stores, supermarkets, or small businesses that only need to read basic 1D codes. 2D scanners, though more expensive initially, have a longer lifespan and offer greater scalability saving costs in the long run, especially for businesses planning to upgrade to 2D codes or integrate with modern management systems (ERP, POS, WMS).

Industry applications

Laser scanners are widely used in retail, supermarkets, warehouses, and traditional logistics environments that demand high-speed scanning and clear printed barcodes.

2D image scanners, however, are more versatile and common in sectors like healthcare, electronics manufacturing, pharmaceuticals, finance, and e-commerce thanks to their ability to handle various code types and flexible data processing. With the growing trend of digital transformation, many companies are choosing 2D scanners to ensure compatibility with QR codes on invoices, product packaging, and digital payment platforms.

Technological trends and future outlook

The market is witnessing a strong shift from laser to 2D scanning technology. This evolution is driven not only by the comprehensive reading capabilities of image-based scanners but also by their connectivity and integration flexibility. Many modern 2D scanners now support Bluetooth, Wi-Fi, and USB-C connections, enabling seamless integration with tablets, POS systems, and mobile devices.

Furthermore, AI-based decoding and deep learning technologies are being incorporated into 2D scanners, allowing them to recognize codes faster, more accurately, and even recover heavily damaged barcodes. This represents a major leap forward in the future of barcode scanning.

Conclusion

Both laser barcode scanners and 2D image scanners play vital roles in data collection and inventory management. The right choice depends on your business needs:

-

If you value speed, simplicity, and cost efficiency, a laser scanner is a practical choice.

-

If you need versatility, durability, and long-term compatibility, a 2D image scanner is a smarter investment.

As QR codes and intelligent management systems become increasingly prevalent, 2D scanners are emerging as the new industry standard. Understanding the strengths and limitations of each technology will help your business make informed decisions optimizing cost, improving workflow efficiency, and staying ahead in the digital age.

Contact Beetech for expert consultation on barcode – RFID – and warehouse automation solutions:

📧 Email: info@beetech.com.vn

🌐 Website: https://beetech.com.vn

See more products: Here